Key takeaways

1. Urgent Call for Reindustrialization: America must revitalize its declining industrial base, addressing the critical loss of industrial capacity to global competitors like China

2. Deepening Industrial Decline: The US faces stark reductions in essential manufacturing sectors, including steel and aluminum production, defense, medical supplies, and critical minerals that exacerbate vulnerabilities in national security and economic resilience

3. Strategic Industrial Policy and Revival: The path to restoring America's industrial power involves targeted government incentives and enacting policies to foster innovation, skilled workforce development, and advanced manufacturing

America needs to reindustrialize. There is currently bipartisan support for industrial policy, the governmental direction of capital to support specific industrial goals.

The 2022 $280 billion CHIPS and Sciences Act incentivized domestic semiconductor manufacturing and the 2022 $891 billion Inflation Reduction Act (IRA) supported domestic clean-energy and battery manufacturing. Although these hi-tech sectors are undoubtably important, America lacks basic industrial capacity crucial to any modern economy while China has become the workshop for the world. It is also clear that these bills, significant though they may be and massive by the standards of history, have done little to establish a political realignment and fall far short of what’s needed.[i]

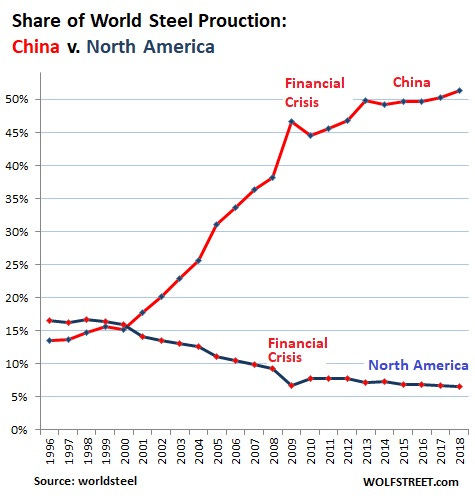

Steel production in the US peaked in 1973[ii] but production is down 62% today. By contrast, China's steel production is 1,030 million tons (12x the US)[iii]. US aluminum production peaked in 1980[iv], but today production is down 81%. In 2022, China’s aluminum output was 40 million tons[v] (40x the US).

Figure 1: China vs North America steel production

The US defense industrial base is no different. China has 200x the shipbuilding capacity of the US[vi]. According to the Defense Department, the number of major defense firms (“primes”) dropped from 107 in 1980 to 5 by the end of the 1990s. By the 2020s, the top defense contractors included only Lockheed Martin, Boeing, Northrop Grumman, General Dynamics, and Raytheon. Along with “prime” contractors, the number of Tier 1 and Tier 2 suppliers has also shrunk by tens of thousands since the 1980s.

America’s dependence on China for medical supplies was obvious during the COVID-19 pandemic. In 2019, China accounted for 53% of US personal protective equipment imports[vii]. Approximately 80% of the Active Pharmaceutical Ingredients used to manufacture drugs in the US come from China and other countries like India[viii]. China supplied 39% of the medical device imports to the US, ranking first among countries that export medical devices to the US[ix].

The United States is heavily reliant on China for critical minerals, pivotal for the national defense and economy. Critical minerals are used in manufacturing a range of products from batteries to computer chips to military equipment. The US Geological Survey warned that of the 50 minerals identified in the “2022 Final List of Critical Minerals,” the United States was 100% net import reliant for 12, and an additional 31 critical mineral had a net import reliance greater than 50%[x]. A notable aspect of this reliance is rare earth elements, which were primarily produced in the US during the 1970s but are now almost entirely produced in China[xi].

It is critical for the US to reshore its lost industrial base, using federal government incentives to direct capital into strategic industrial sectors. This post and following series of white papers will discuss which sectors are strategic and how to revive them.

Failure of free trade

The US federal government greatly expanded during the New Deal-era. This expansion included major intervention into the private economy, which expanded even further during the WW2 mobilization. Then in the 1950s and 1960s, the US economy enjoyed a broad-based economic expansion. Economic trouble in the 1970s led to deregulation and the undoing of the New Deal political economy. By the 1990s, free trade and globalization were the new normal.

In 2008, imbalances resulting from unfettered free trade nearly blew up the global financial system and by the mid-2010s, the US had entered what economist Larry Summers called “secular stagnation”. Jobs had been offshored to low labor cost jurisdictions around the world, the middle-class was hollowed out, and the industrial heart had been ripped out of the Midwest (see American Deindustrialization). By the 2020s, a raft of social problems had taken hold, including a massive drug crisis, declining lifespans, and extreme political polarization.

All of these problems, and many more, can be traced to the decline of the US industrial base due to unfettered free trade. Therefore, the overriding goal of US policy, both foreign and domestic, must be to reindustrialize and export goods to the global middle class.

Industrial policy mechanisms

The CHIPS Act and the IRA have made tax incentives and subsidies available for certain qualifying hi-tech projects, validating that the private sector will respond to industrial policy with investment. $224 billion[xii] in new manufacturing facilities have been announced due to the IRA and CHIPS, according to the Financial Times. Restoring America’s industrial base will require lowering the corporate tax rate for qualifying industrial projects, and targeted tax credits and interest-free loans to four strategic sectors: 1) steel, aluminum, and other derivative metal projects, 2) defense and shipbuilding projects, 3) medical supplies projects and 4) critical minerals projects. Additionally, antitrust action should be conducted in the overly-consolidated defense sector.

Restoring industrial capacity alone is not enough. The federal government should also enact policies to spur innovative advanced manufacturing processes and foster the development of a skilled workforce. Alexander Hamilton proposed tariffs in the 18th-century to develop American manufacturing and 19th-century policymakers continued those tariffs. America should impose a global tariff on all imported manufactured goods to promote US manufacturing.

Decentralized model

One of the chief criticisms of industrial policy is about concerns of over-centralization. Industrial policy is unfairly compared to Soviet central panning. It’s true that overall policy direction should be top-down, we recommend a Manufacturing Czar reporting to the President leading the initiative, but innovation and execution should happen in decentralized networks across the country. Universities, the private sector, federal labs, state and local government, the military, and more should take part. The overall effort should be nationally recognized, like the Marshall Plan or Operation Warp Speed.

Restoring America

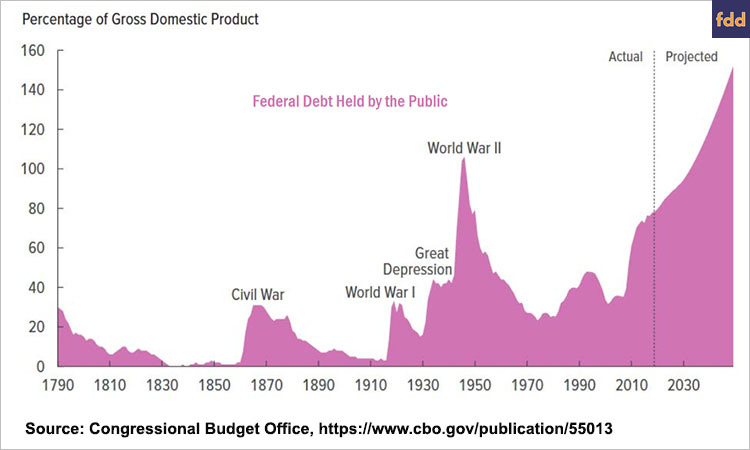

Over time, this industrial rebuilding will have numerous benefits. First, it will create many, good, middle-class jobs and economic growth. Second, the economic growth will create significant new tax revenue to close the growing and unsustainable federal budget deficit.

Figure 2: US federal debt

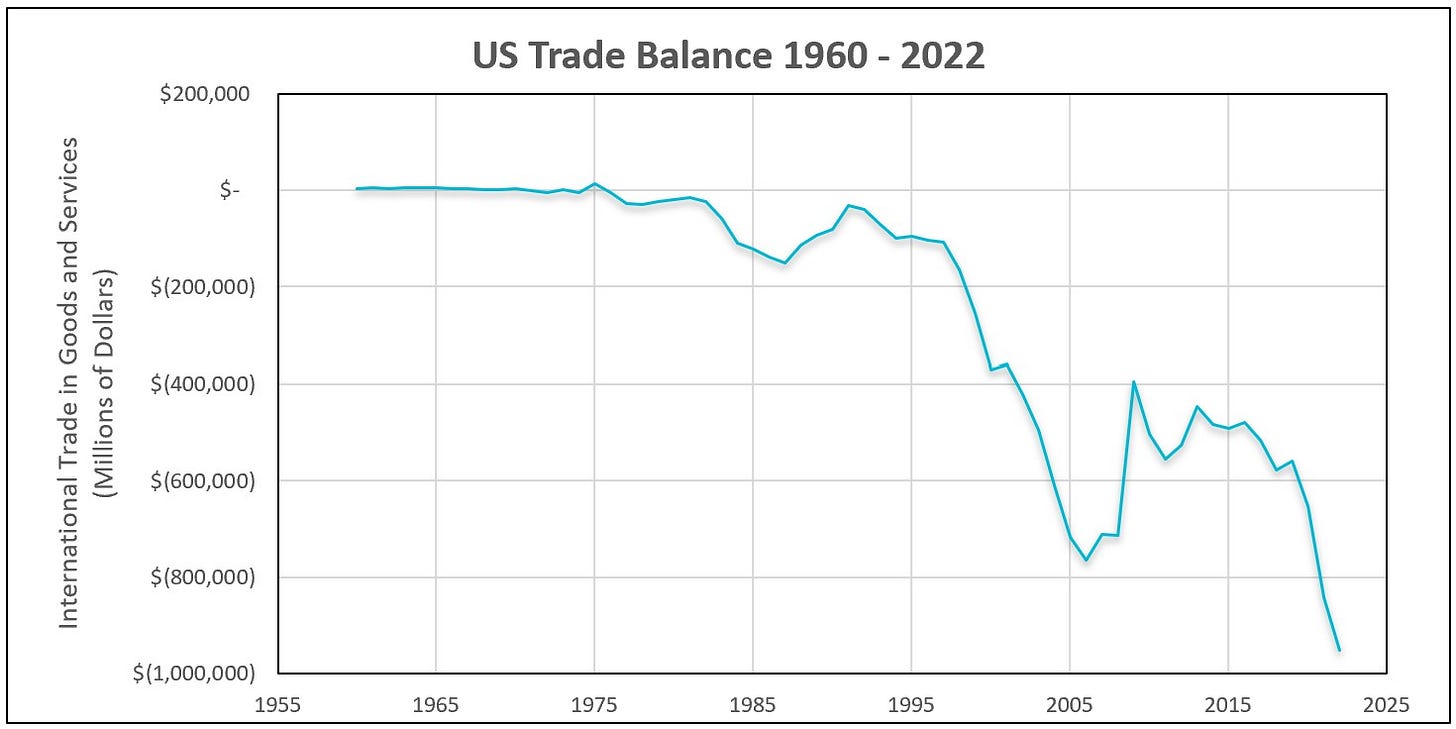

Third, it will reduce America’s structural trade deficit with the world. Fourth, reducing the trade deficit will bring down inflation and multi-decade high interest rates. Finally, restoring America’s industrial base will end our reliance on China, our greatest geopolitical rival, and improve national security.

Figure 3: US trade deficit[xiii]

The pivotal nature of a vibrant, self-reliant industrial sector to a nation's economic prosperity, security, and geopolitical influence cannot be overstressed. The US, once an industrial titan, has witnessed the erosion of its core manufacturing capabilities, making it vulnerable in various sectors, including basic metals, defense, healthcare, and critical minerals. Globalization, free trade policies, and the unchecked reliance on international suppliers, especially China, have culminated in pressing national challenges. If executed effectively, these initiatives can not only revive the industrial heart of America but also ensure its robustness against future uncertainties. Embracing this resurgence is more than an economic imperative; it's a clarion call to rebuild, reinvent, and reclaim the American Dream for future generations.

[ii] https://blog.gitnux.com/us-steel-production-statistics/#:~:text=US%20stainless%20steel%20melt%20shop,behind%20China%2C%20Japan%2C%20and%20India

[iii] https://www.statista.com/statistics/448869/steel-production-volume-in-china/#:~:text=Steel%20production%20volume%20in%20China,9%20percent

[iv] https://en.wikipedia.org/wiki/Aluminum_industry_in_the_United_States

[v] https://www.reuters.com/markets/commodities/chinas-2022-aluminium-output-hits-record-high-4021-mln-tonnes-2023-01-17/#:~:text=China%27s%20annual%20aluminium%20output%20in,from%20newly%20launched%20capacity

[vi] https://www.thedrive.com/the-war-zone/alarming-navy-intel-slide-warns-of-chinas-200-times-greater-shipbuilding-capacity

[vii] https://www.statista.com/statistics/1122414/select-us-imports-from-china-medical-supplies-under-tariff-exclusions/#:~:text=Jul%2020%2C%202020%20The%20Chinese,imports%20of%20selected%20medical%20equipment

[viii] https://www.cfr.org/blog/us-dependence-pharmaceutical-products-china

[ix] https://www.fda.gov/news-events/congressional-testimony/exploring-growing-us-reliance-chinas-biotech-and-pharmaceutical-products-07312019#:~:text=China%20provides%2039,is%20imperative%20FDA%20continues%20to

[x] https://nma.org/2023/01/31/u-s-reaches-highest-recorded-mineral-import-reliance/#:~:text=Of%20the%2050%20mineral%20commodities,of%20apparent%20consumption

[xi] https://www.doi.gov/pressreleases/groundbreaking-report-us-reliant-china-russia-other-foreign-nations-many-critical

[xii] https://www.ft.com/content/3b19c51d-462b-43fa-9e0e-3445640aabb5?shareType=nongift

[xiii] https://www.higherrockeducation.org/glossary-of-terms/balance-of-trade